Dry Film Thickness (DFT) to Wet Film Thickness (WFT) Calculator

In the world of painting and coatings, achieving the perfect finish requires precise calculations. One of the critical parameters in this process is the relationship between Wet Film Thickness (WFT) and Dry Film Thickness (DFT). Understanding how to convert between these two measurements is essential for ensuring that your coatings perform as intended, both in terms of aesthetics and durability.

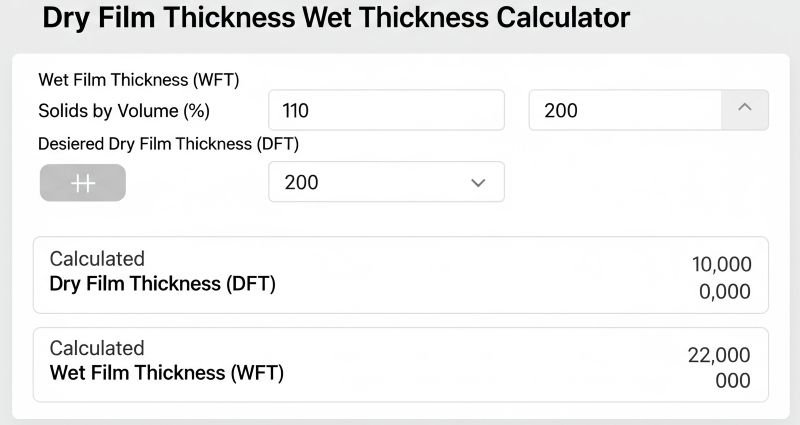

This user-friendly tool simplifies the process of determining the necessary wet film thickness based on your desired dry film thickness and the solids by volume (SBV) of your coating. For instance, if you need a dry film thickness of 6 mils but are using a coating with 30% solids by volume, our calculator can quickly show you the correct wet film thickness to apply.

WFT to DFT Calculator

Example Calculation

To calculate Wet Film Thickness (WFT), you can use the formula:

WFT=DFT/ SBV

Imperial and Metric Units

Let’s consider a scenario where we have a coating with 30% solids by volume, and we need to achieve a dry film thickness of 6 mils (or 152 µm). To begin, we convert the percentage of solids to a decimal by moving the decimal point two places to the left. For instance, 30% becomes 0.30. We can then apply the values to our formula:

- For a coating with 30% SBV: – WFT=6 mils/ 0.30=20 mils (508 μm)

Now, let’s look at another example where we have a coating with 35% solids by volume and a target dry film thickness of 125 µm. We will again use the same formula:

- For a coating with 35% SBV: WFT=125 μm/ 0.35≈357 μm

These examples illustrate how to effectively calculate the required wet film thickness based on your desired dry film thickness and the solids by volume of the coating.

Additional Example Calculations

Example 1: Coating with 25% Solids by Volume

Suppose we have a coating that contains 25% solids by volume, and we want to achieve a dry film thickness of 4 mils (approximately 102 µm). First, we convert the percentage into a decimal by moving the decimal point two places to the left, transforming 25% into 0.25. We then use the formula:

- For a coating with 25% SBV: WFT=4 mils/ 0.25=16 mils (406 μm)

Example 2: Coating with 50% Solids by Volume

In another scenario, consider a coating with 50% solids by volume, and we need to achieve a dry film thickness of 10 mils (254 µm). Converting 50% to a decimal gives us 0.50. We apply this to our formula:

- For a coating with 50% SBV: WFT=10 mils/ 0.50=20 mils (508 μm)

Example 3: Coating with 20% Solids by Volume

Consider a coating that has 20% solids by volume, and we aim for a dry film thickness of 5 mils (127 µm). First, we convert 20% into a decimal, resulting in 0.20. Using our formula gives us:

- For a coating with 20% SBV: WFT=5 mils/ 0.20=25 mils (635 μm)

Example 4: Coating with 15% Solids by Volume

Lastly, let’s examine a coating with 15% solids by volume, where we need a dry film thickness of 8 mils (203 µm). Converting 15% to a decimal gives us 0.15. We can then calculate:

- For a coating with 15% SBV: WFT=8 mils/ 0.15≈53.33 mils (1356 μm)

These examples demonstrate how to calculate the required wet film thickness for various solid contents and desired dry film thicknesses, helping you ensure optimal application of coatings.

Why Calculate WFT from a DFT Specification?

Calculating the target wet thickness is the only way to ensure “Right First Time” application.

- Prevent Under-thickness: Avoid the need for costly second coats or “touch-ups” after the paint has cured.

- Prevent Over-thickness: Excessive thickness in coatings like Inorganic Zinc (IOZ) can lead to “mud-cracking,” while in epoxies, it can cause solvent entrapment.

- Material Estimating: Accurate WFT targets help project managers estimate the total liters of paint required for the job.

The Mathematics of Target Wet Thickness

The calculator uses the inverse of the standard coating formula. To find the wet target, we must “expand” the dry solids requirement by the amount of solvent that will evaporate.

1. The Standard Formula (No Thinner)

When applying paint straight from the container:

$$WFT = \frac{DFT \times 100}{\text{Volume Solids %}}$$

2. The Adjusted Formula (With Thinner Added)

If you have added thinner to the mix, the wet volume increases, meaning you must apply a thicker wet layer to achieve the same dry result:

$$WFT = \frac{DFT \times (100\% + \text{% Thinner Added})}{\text{Volume Solids %}}$$

Industry Benchmarks: DFT Requirements vs. Target WFT

Different environments (C3 to C5 corrosive categories) require different dry film builds. Here are common targets for structural steel in Australia:

| Required DFT (μm) | Coating Type | Volume Solids | Target WFT (μm) |

| 75 μm | Zinc Primer | 62% | 121 μm |

| 200 μm | Epoxy Mastic | 80% | 250 μm |

| 50 μm | Polyurethane | 55% | 91 μm |