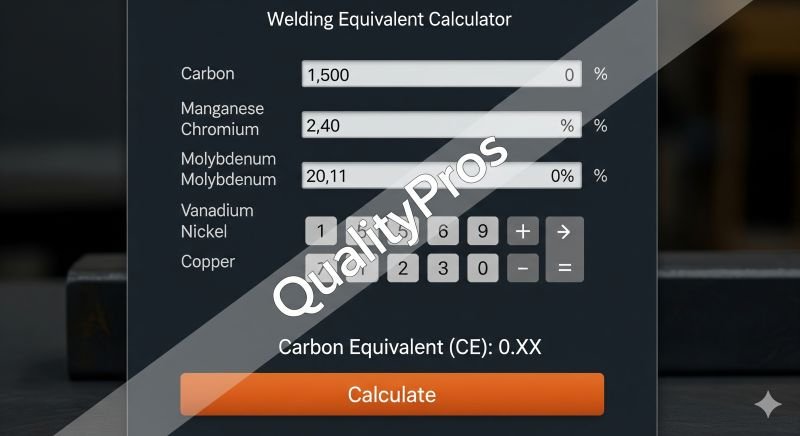

Welding Carbon Equivalent Calculator

Quickly calculate the Carbon Equivalent (CE) of steel to assess weldability and preheat requirements. This tool helps engineers, welders, and inspectors determine the risk of cracking and select appropriate welding procedures.

Carbon Equivalent Calculator

What is carbon equivalent in Welding?

The carbon equivalent (CE) is a calculated value used to assess the weldability and hardenability of steel. It provides an indication of how the composition of a steel alloy affects its properties, particularly when it comes to welding and heat treatment. The formula for calculating the carbon equivalent varies depending on the specific alloying elements present in the steel.

Carbon Equivalent formula in Welding

- For Low-Alloy Steels:

CE=%C+6%Mn+5%Cr+%Mo+%V+15%Cu+%Ni

- C: Carbon content (in weight %)

- Mn: Manganese content (in weight %)

- Cr: Chromium content (in weight %)

- Mo: Molybdenum content (in weight %)

- V: Vanadium content (in weight %)

- Ni: Nickel content (in weight %)

- Cu: Copper content (in weight %)

For Carbon Steels:

CE=%C+%Mn/6

This formula is a simplified version and is often used for carbon steels where only carbon and manganese are considered.

For Welding Applications:

- A more specific CE formula for evaluating weldability is:

CE=C+Mn/6+(P+S)/15

- P: Phosphorus content (in weight %)

- S: Sulfur content (in weight %)

Carbon Equivalent formula for Cast Iron

The Carbon Equivalent (CE) formula for cast iron is used to predict the behavior of the alloy during heat treatment and casting. It helps in understanding the balance between austenite and graphite in the final structure. The commonly used formula for calculating the Carbon Equivalent in cast iron is:

CE=%C+%Si/3+%P/3+%S/3+%Mn/3

This formula takes into account the percentages of carbon (C), silicon (Si), phosphorus (P), sulfur (S), and manganese (Mn) in the cast iron.

IIW Carbon Equivalent Formula

The International Institute of Welding (IIW) Carbon Equivalent (CE) formula is widely used to assess the weldability of steel. The formula is as follows:

CE=%C+%Mn/6+(%Cr+%Mo+%V)5+(%Cu+%Ni)15

This formula takes into account the percentages of carbon (C), manganese (Mn), chromium (Cr), molybdenum (Mo), vanadium (V), copper (Cu), and nickel (Ni) in the steel.

The IIW formula is particularly useful for predicting the hardenability and the risk of hydrogen-induced cold cracking in the heat-affected zone (HAZ) during welding

1. Understanding and calculating the Carbon Equivalent using this formula helps in selecting appropriate welding techniques and pre-weld preparations to ensure high-quality welds.

Interpretation of Carbon Equivalent

- Lower CE Values: Indicate better weldability. Generally, a CE value of less than 0.35% is considered good for weldability.

- Higher CE Values: Indicate a greater tendency for cracking and reduced weldability. Steels with a CE value above 0.45% may require special welding techniques or preheat treatments.

Why is Carbon Equivalent Important?

The Carbon Equivalent is crucial because it helps predict the behavior of steel during welding, particularly in terms of hardening and the risk of cracking. Here are some key reasons why CE is important:

- Hardenability: CE indicates a material’s ability to harden during the welding process. A higher CE value typically means a greater risk of hardening, which can lead to weld cracking. Conversely, a lower CE value signifies better weldability.

- Risk of Cracking: High CE values are associated with an increased risk of cracking, especially when the material is exposed to rapid temperature changes during welding. This can compromise the integrity of the weld and the overall structure.

- Selection of Welding Techniques: Welders use CE values to determine the most appropriate welding techniques and consumables for a specific material. Materials with higher CE values may require preheating, post-weld heat treatment, or the use of low-hydrogen electrodes to reduce the risk of cracking.

- Pre-Weld Preparation: CE values guide the preparation of materials before welding. For materials with higher CE values, it is essential to perform proper pre-weld cleaning, control interpass temperatures, and utilize preheat methods to minimize the risk of defects.

Maximum carbon equivalent for weldability

The maximum carbon equivalent (CE) for good weldability varies depending on the specific standards and practices in different industries. However, a general guideline is as follows:

Maximum Carbon Equivalent Values

- Low-Alloy Steels:

- A CE value of ≤ 0.35% is often considered suitable for good weldability. Steels with this level of carbon equivalent are less prone to cracking during welding.

- Carbon Steels:

- For carbon steels, the maximum CE for acceptable weldability is typically around 0.45%. Above this value, the risk of cracking increases significantly.

- Welding Applications:

- In many welding applications, a CE value exceeding 0.50% is generally regarded as problematic. Special precautions, such as preheating or post-weld heat treatment, may be required for steels with higher CE values.

Summary

- Good Weldability: CE ≤ 0.35%

- Acceptable Weldability: CE ≤ 0.45%

- Potential Issues: CE > 0.50%