Welding preheat is a critical step in ensuring weld quality, especially when working with thicker materials or high-carbon steels. But calculating the right preheat temperature can be time-consuming and error-prone.

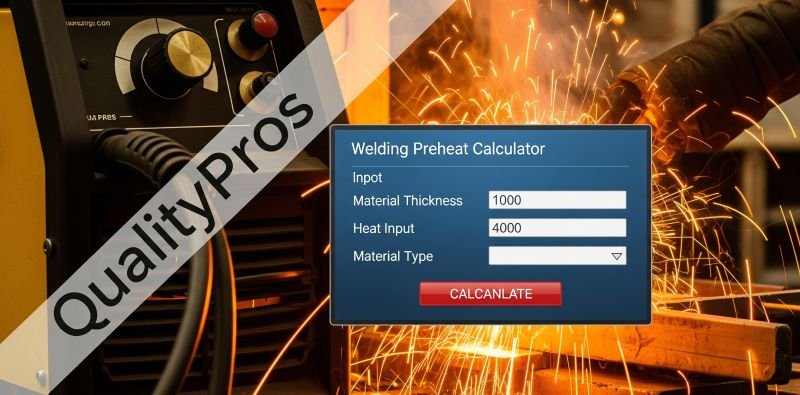

That’s why I created a Welding Preheat Calculator – a simple, practical tool to help welders, inspectors, and engineers quickly determine the recommended preheat temperature based on:

✅ Material type

✅ Thickness

✅ Carbon Equivalent (CE)

It also includes a reference table with preheat guidelines for commonly used materials like carbon steel, alloy steel, stainless steel, and cast iron.

Whether you’re preparing a Welding Procedure Specification (WPS) or working on-site, this tool helps ensure you’re applying the correct preheat to reduce cracking and improve weld integrity.

🔧 Steps for Welding Preheat Calculation

Preheating is essential to reduce the risk of cracking, especially in thick or high-carbon steels. Here’s how to calculate or determine the required preheat temperature:

1. Identify Material Properties

- Type of base metal (e.g., carbon steel, alloy steel, stainless steel)

- Thickness of the material

- Carbon Equivalent (CE) value

2. Calculate Carbon Equivalent (CE)

For steels, use the formula:

CE=C+Mn6+Cr+Mo+V5+Ni+Cu15CE=C+6Mn+5Cr+Mo+V+15Ni+Cu

This helps assess the hardenability and cracking risk.

3. Refer to Welding Codes/Standards

Use standards like:

- AWS D1.1 (Structural Welding Code – Steel)

- ASME Section IX

- EN 1011

These provide guidelines based on CE and material thickness.

4. Determine Joint Type and Restraint Level

Highly restrained joints require higher preheat.

5. Use Preheat Charts or Software

Charts or calculators based on CE and thickness can give recommended temperatures.

6. Consider Ambient Conditions

Cold environments may require increased preheat.

📊 Recommended Preheat Temperatures for Common Materials

| Material | Thickness (mm) | Carbon Equivalent (CE) | Recommended Preheat (°C) |

|---|---|---|---|

| Carbon Steel (A36) | < 25 | < 0.40 | 20–50 |

| Carbon Steel (A36) | > 25 | 0.40–0.60 | 100–150 |

| Low Alloy Steel (AISI 4140) | < 25 | 0.45–0.60 | 150–200 |

| Low Alloy Steel (AISI 4140) | > 25 | > 0.60 | 200–300 |

| Stainless Steel (304/316) | Any | N/A | Typically not required |

| Cast Iron | Any | High | 300–600 |

| High Strength Low Alloy (HSLA) | > 25 | > 0.45 | 100–200 |

🔍 Note: Always consult the welding procedure specification (WPS) and applicable codes for exact values.

Good information