Understanding Pitting Corrosion Resistance Number (pRen)

Pitting corrosion refers to the localized form of corrosion that leads to the creation of small holes or pits in a material. The pitting corrosion resistance number, or pRen, is a crucial metric in evaluating how resistant a material is to this type of corrosion. Calculating pRen can aid engineers and material scientists in choosing appropriate materials for various applications, especially in environments prone to corrosive attacks.

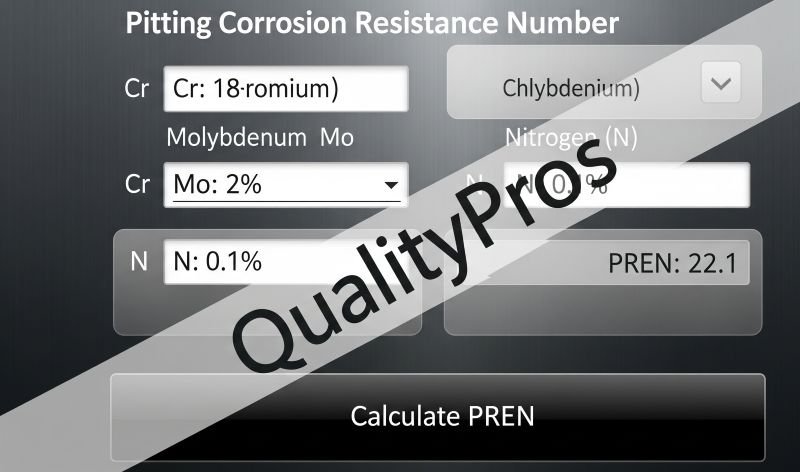

Pitting Corrosion Resistance Number (pRen) Calculator

Pitting Corrosion Resistance Number (pRen) Calculator

What is Pitting Corrosion? 🕳️

Pitting corrosion is a localized form of degradation that creates small, deep holes or “pits” on a metal’s surface, particularly stainless steels and alloys with protective oxide films. Unlike uniform corrosion, pitting is insidious because it can lead to structural failure with minimal material loss. It’s often triggered by chloride ions (e.g., in seawater), poor aeration, or chemical exposure, which break down the passive oxide layer, allowing pits to grow rapidly in acidic, self-sustaining conditions. Once initiated, pits are hard to stop, making material selection critical.

For example, in a marine pipeline, pitting corrosion could perforate tubing walls, causing leaks and costly downtime. This aligns with performance issues like delayed NDT report management or non-standard documentation, where proactive measures (like choosing the right alloy) prevent escalation, as emphasized in quality management systems.

What is PREn? 📊

The Pitting Resistance Equivalent Number (PREn) is a theoretical metric that predicts a material’s resistance to pitting corrosion based on its chemical composition. It’s widely used to rank and compare stainless steels and corrosion-resistant alloys, especially in chloride-rich environments like seawater or chemical plants. A higher PREn indicates greater resistance to pitting, guiding engineers in selecting materials for demanding applications. However, PREn is not an absolute predictor of performance and must be considered alongside environmental factors and engineering requirements.

PREn is particularly valuable in industries where material failure could lead to safety hazards or economic losses, much like how proactive task ownership in a QMS prevents workflow disruptions.

How is PREn Calculated? 🧮

PREn is derived from the weight percentages of key alloying elements known to enhance pitting resistance. The most common formulas are:

- Standard Formula (for stainless and duplex alloys without tungsten):

PREn = %Cr + 3.3 × %Mo + 16 × %N

This formula emphasizes chromium (Cr), molybdenum (Mo), and nitrogen (N), with coefficients reflecting their relative impact on corrosion resistance. - Modified Formula (for super duplex alloys with tungsten):

PREn = %Cr + 3.3 × (%Mo + 0.5 × %W) + 16 × %N

This includes tungsten (W), which enhances pitting resistance in certain alloys like super duplex stainless steels.

Key Alloying Elements and Their Roles

- Chromium (Cr): Forms a stable, self-healing oxide layer (Cr₂O₃) that protects against corrosion. Typically 10.5–30% in stainless steels, higher Cr content boosts PREn.

- Molybdenum (Mo): Enhances the oxide layer’s stability in chloride environments, increasing repassivation potential. Its coefficient (3.3) reflects its strong impact.

- Nitrogen (N): Stabilizes the oxide layer and improves repassivation, especially in crevices. Despite low concentrations (<1%), its high coefficient (16) underscores its potency.

- Tungsten (W): Similar to molybdenum, it enhances pitting resistance in super duplex alloys, with a coefficient of 0.5 to reflect its lesser but notable effect.

For example, a 304 stainless steel with 18% Cr, 0% Mo, and 0% N might have a PREn of ~18, while a super duplex 2507 with 25% Cr, 4% Mo, 0.3% N, and 0.5% W could reach a PREn of ~40, indicating superior resistance.

Typical PREn Values and Their Significance 📈

PREn values typically range from 16 to over 40, with higher values indicating better resistance to pitting corrosion. Here’s a breakdown:

- PREn < 20: Low resistance (e.g., 304 stainless steel). Suitable for mild environments but not chloride-rich settings.

- PREn 20–30: Moderate resistance (e.g., 316 stainless steel). Adequate for some industrial applications but not seawater.

- PREn 30–40: Above-average resistance. Stainless steels with PREn > 32 may resist seawater corrosion under optimal conditions.

- PREn ≥ 40: High resistance (e.g., super duplex or super austenitic alloys). Ideal for harsh environments like seawater or hydrogen sulfide settings, often required by standards like ISO 15156/NACE MR0175.

For instance, in oil and gas extraction, duplex steels with PREn ≥ 40 are specified for hydrogen sulfide environments, ensuring durability where failure is not an option.

Practical Applications of PREn 🛠️

PREn is a cornerstone in material selection for industries facing corrosive challenges:

- Marine Engineering: Selecting alloys for seawater pipelines or ship components to prevent pitting-induced leaks.

- Oil and Gas: Choosing tubing for offshore platforms where chloride and hydrogen sulfide exposure is high.

- Chemical Processing: Ensuring heat exchangers and valves withstand aggressive chemical environments.

- Desalination Plants: Using high-PREn alloys for components exposed to saline water.

For example, a QA/QC team selecting materials for a desalination plant would prioritize super duplex alloys (PREn ≥ 40) to meet performance expectations, avoiding issues like delayed NDT reports or non-standard documentation by ensuring compliance with material standards.

Limitations of PREn ⚠️

While PREn is a powerful tool, it has limitations, much like how a QMS requires proactive engagement to address performance gaps:

- Limited to Same Alloy Family: PREn comparisons are only valid within the same stainless steel family (austenitic, ferritic, duplex). A PREn of 42 in a duplex alloy doesn’t guarantee better performance than a 41 in an austenitic alloy.

- Environmental Factors: PREn doesn’t account for non-chloride corrosives, temperature, surface finish, or system design, which significantly affect corrosion.

- Not Absolute: A 0.5 difference in PREn doesn’t ensure better performance. It’s a ranking tool, not a definitive predictor.

- Excludes Other Factors: PREn ignores heat treatment, surface roughness, or inclusions, which impact pitting resistance.

- Not for Nickel Alloys: Standard PREn formulas don’t apply to nickel-based alloys like Inconel 625, which require modified calculations.

For instance, a manager addressing a backlog in material test certificates would recognize that relying solely on PREn without verifying surface conditions or heat treatment could lead to suboptimal material choices, akin to using non-QA documents in inspections.

Connecting PREn to Quality Management Principles 🤝

The PIP feedback emphasizes timely documentation, proactive behavior, and QA compliance, which parallel PREn’s role in quality-driven material selection. Just as employees must eliminate backlogs and use standardized tools, engineers must select high-PREn alloys and verify their suitability through testing (e.g., ASTM G48). Proactive material choices prevent corrosion-related failures, reducing managerial overload and ensuring compliance with standards like ISO 9001:2026, which stresses risk management and process efficiency.

How to Use PREn Effectively: A Practical Guide 📋

To leverage PREn while addressing its limitations, follow these steps, mirroring PIP strategies for accountability and efficiency:

- Calculate PREn: Use alloy composition data and the appropriate formula (standard or tungsten-inclusive) to rank materials.

- Compare Within Families: Ensure comparisons are within the same alloy family for accuracy.

- Consider Environment: Evaluate chloride levels, temperature, and acidity. For seawater, target PREn ≥ 32; for critical applications, aim for ≥ 40.

- Verify with Testing: Use ASTM G48 or G150 to confirm pitting resistance, as PREn is theoretical.

- Consult Engineers: Engage experts to assess surface finish, heat treatment, and system design, ensuring comprehensive material selection.

- Document Choices: Maintain records of PREn calculations and testing results, aligning with QMS documentation standards to avoid backlogs.

- Train Teams: Educate QA/QC teams on PREn and its limitations, fostering proactive material selection akin to PIP’s emphasis on initiative.

Example: Material Selection for a Seawater Pipeline 🌊

Suppose a QA/QC team is selecting tubing for a seawater pipeline. They calculate PREn for three alloys:

- 316 Stainless Steel: 17% Cr, 2% Mo, 0.1% N → PREn = 17 + (3.3 × 2) + (16 × 0.1) = 25.2 (insufficient for seawater).

- Duplex 2205: 22% Cr, 3% Mo, 0.2% N → PREn = 22 + (3.3 × 3) + (16 × 0.2) = 35.1 (marginal for seawater).

- Super Duplex 2507: 25% Cr, 4% Mo, 0.3% N, 0.5% W → PREn = 25 + (3.3 × (4 + 0.5 × 0.5)) + (16 × 0.3) = 41.3 (suitable for seawater).

The team selects 2507, verifies with ASTM G48 testing, and documents the process, ensuring compliance and efficiency, much like meeting PIP expectations for timely NDT updates.

Expert Insights 🗣️

- “PREn is a starting point for material selection, but real-world performance depends on environmental and fabrication factors.”

- “Alloys with PREn ≥ 40, like super duplex, are critical for harsh environments, but testing is essential.”

- “Think of PREn as a ranking tool, not a guarantee. Always consult engineers for final decisions.”

These insights highlight PREn’s role as a comparative metric, requiring proactive validation, much like addressing negative peer feedback through collaboration.

Conclusion: Mastering PREn for Corrosion Resistance 🎉

The Pitting Resistance Equivalent Number (PREn) is a vital tool for selecting corrosion-resistant alloys in chloride-rich environments, offering a numerical ranking based on chromium, molybdenum, nitrogen, and tungsten content. While powerful, it’s not a standalone solution—environmental factors, testing, and expert consultation are crucial for success. By integrating PREn into a QMS framework, teams can make informed, proactive material choices, avoiding pitfalls like corrosion failures or documentation backlogs. Embrace PREn, verify with testing, and keep quality first to ensure durability in the toughest conditions! 💪 Share your thoughts on PREn below or contact an engineer for tailored material advice.