P-Numbers, A-Numbers, and F-Numbers in Welding

In welding, efficiency, safety, and quality are paramount. To achieve these, welding professionals rely on standardized systems to classify materials, filler metals, and welding processes. Among the most critical classification systems are P-Numbers, A-Numbers, and F-Numbers. These numbering systems, primarily defined by the American Society of Mechanical Engineers (ASME), play a vital role in simplifying welding procedures, ensuring compatibility, and maintaining consistency across projects.

This blog post will explain in depth what P-Numbers, A-Numbers, and F-Numbers are, their significance in welding, and how they are referenced in key standards such as ASME, AWS (American Welding Society), ISO (International Organization for Standardization), and AS (Australian Standards). By the end, you’ll have a clear understanding of these essential welding classifications and their practical applications.

Origin of P-Numbers

P-Numbers (Parent Metal Numbers) were introduced by ASME to group base metals with similar weldability characteristics. The system emerged as welding grew more complex, particularly during the development of pressure vessel and piping codes.

- Before P-Numbers, each base metal required a unique welding procedure specification (WPS), which was inefficient. ASME recognized that many metals shared welding behaviors and could be grouped to reduce qualification efforts.

- The P-Number system was formalized in the ASME Boiler and Pressure Vessel Code (BPVC), Section IX, becoming a cornerstone of welding standardization. It assigns numbers based on a metal’s composition, mechanical properties, and weldability.

This classification allows a single WPS to cover multiple materials within the same P-Number, enhancing efficiency and consistency.

Material P-Number and F-Number Calculator

Note: The dropdown includes examples of materials and electrodes. Select the category that matches your specific material.

Origin of A-Numbers

A-Numbers (Analysis Numbers) classify the chemical composition of ferrous weld metal deposits. Their development stemmed from the need to control weld metal properties as welding technology advanced.

- Early welding practices revealed that the weld metal’s chemistry—elements like carbon, manganese, and alloying agents—affects strength, toughness, and corrosion resistance. A-Numbers were created to group weld metals with similar compositions.

- Standardized in ASME BPVC Section IX, A-Numbers ensure that weld deposits meet the required performance criteria for specific applications.

This system simplifies the selection and qualification of weld metals by focusing on their chemical analysis.

Origin of F-Numbers

F-Numbers (Filler Metal Numbers) categorize welding filler metals based on usability characteristics, such as the welding process and operability. They were introduced to address the variability of filler metals in early welding practices.

- As filler metals differed in handling and performance, ASME grouped those with similar characteristics to reduce the number of welder qualifications needed. This was critical for standardizing welder skills across projects.

- Defined in ASME BPVC Section IX, F-Numbers classify filler metals by factors like coating type (for electrodes), flux, and welding process (e.g., SMAW, GTAW).

F-Numbers ensure compatibility between filler metals, welding processes, and welder expertise.

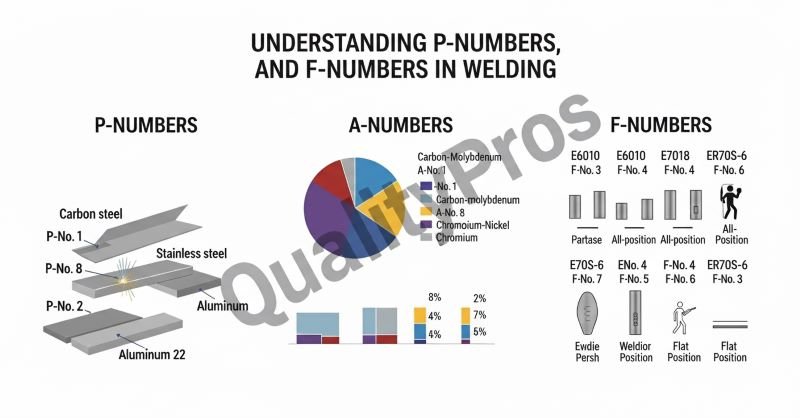

Commonly Used P-Numbers, A-Numbers, and F-Numbers

The table below lists examples of commonly used P-Numbers, A-Numbers, and F-Numbers, illustrating their application in welding.

| Classification | Number | Description | Examples |

|---|---|---|---|

| P-Number | 1 | Carbon steels | ASTM A36, A516 |

| 8 | Austenitic stainless steels | 304, 316 | |

| 10H | Duplex stainless steels | 2205, 2507 | |

| 5A | 2.25% Cr – 1% Mo steels | ASTM A387 Gr. 22 | |

| A-Number | 1 | Carbon steel weld deposits | E7018 weld metal |

| 8 | Stainless steel weld deposits | ER308L weld metal | |

| 2 | Low-alloy steel weld deposits | E8018-B2 weld metal | |

| F-Number | 1 | High-deposition SMAW electrodes | E7024 |

| 4 | Low-hydrogen SMAW electrodes | E7018 | |

| 6 | Tubular cored electrodes (FCAW) | E71T-1 | |

| 43 | Aluminum alloy electrodes | ER4043 |

What is a P-Number in Welding?

Definition and Purpose

A P-Number (short for “Parent Metal Number”) is a classification system used to group base metals with similar weldability characteristics. This system simplifies the qualification of welding procedures by allowing welders to use a single procedure for multiple metals within the same P-Number group.

- Primary Standard: ASME Boiler and Pressure Vessel Code (BPVC), Section IX.

- Purpose: To reduce the number of welding procedure qualifications required by grouping metals with similar properties.

How P-Numbers Are Assigned

P-Numbers are assigned based on the base metal’s composition, mechanical properties, and weldability. For example:

- P-Number 1: Carbon steels (e.g., ASTM A36, A516).

- P-Number 8: Austenitic stainless steels (e.g., 304, 316).

- P-Number 10H: Duplex stainless steels.

A full list of P-Numbers can be found in ASME BPVC Section IX, Table QW-422.

P-Numbers group base metals with similar weldability characteristics, covering a wide range of materials like carbon steels, stainless steels, and nickel alloys.

| P-Number | Description | Examples of Base Metals |

|---|---|---|

| 1 | Carbon steels | ASTM A36, A516, A106, A285 |

| 3 | Low-alloy steels (e.g., 0.5% Mo) | ASTM A204, A335 P1, A182 F1 |

| 4 | Low-alloy steels (e.g., 1.25% Cr – 0.5% Mo) | ASTM A387 Gr.11, A335 P11, A182 F11 |

| 5A | Low-alloy steels (e.g., 2.25% Cr – 1% Mo) | ASTM A387 Gr.22, A335 P22, A182 F22 |

| 5B | Low-alloy steels (e.g., 5% Cr – 9% Cr) | ASTM A387 Gr.5, A335 P5, A182 F5 |

| 6 | Martensitic stainless steels | ASTM A240 Tp410, A268 Tp410 |

| 7 | Ferritic stainless steels | ASTM A240 Tp430, A268 Tp430 |

| 8 | Austenitic stainless steels | ASTM A240 Tp304, Tp316, A312 Tp321 |

| 9A | Nickel steels (e.g., 2.5% Ni) | ASTM A203 Gr.A, A352 LC2 |

| 10A | Manganese-vanadium steels | ASTM A225 Gr.C, A572 Gr.65 |

| 10H | Duplex stainless steels | ASTM A240 S31803, S32205 (2205), S32750 (2507) |

| 11A | Quenched and tempered steels | ASTM A514, A517, A709 Gr.100 |

| 15E | 9% Cr – 1% Mo – V steels (e.g., P91) | ASTM A387 Gr.91, A335 P91, A182 F91 |

| 21-25 | Aluminum and aluminum alloys | ASTM B209 (6061), B221 (7075) |

| 41-47 | Nickel and nickel alloys | ASTM B162 (Nickel 200), B564 (Inconel 600) |

| 51-53 | Titanium and titanium alloys | ASTM B265 (Ti Gr.2), B348 (Ti Gr.5) |

Importance in Welding

- Simplifies Procedure Qualification: A welding procedure qualified for one metal in a P-Number group can be used for other metals in the same group without requalification.

- Ensures Compatibility: Helps in selecting appropriate filler metals and welding processes for specific base metals.

References in Other Standards

- ISO 15608: Similar to P-Numbers, ISO uses “Material Groups” (e.g., Group 1 for carbon steels). ISO standard 15608 covers material group numbers.

- AS Standards: Australian standards often reference ASME P-Numbers for welding qualifications.

What is an A-Number in Welding?

Definition and Purpose

An A-Number (short for “Analysis Number”) classifies the chemical composition of ferrous weld metal deposits (i.e., the weld itself, not the base metal). This classification is crucial for ensuring that the weld metal has the desired properties for the application.

- Primary Standard: ASME BPVC Section IX.

- Purpose: To group weld metals based on their chemical composition, particularly for ferrous materials.

A-Numbers classify the chemical composition of ferrous weld metal deposits based on elements like carbon, manganese, silicon, and alloying elements.

| A-Number | Description | Examples of Weld Metal Deposits |

|---|---|---|

| 1 | Carbon steel | E7018, E6010 (SMAW electrodes) |

| 2 | Carbon-molybdenum steel | E8018-B2, E9018-B3 (low-alloy steel electrodes) |

| 3 | Chromium-molybdenum steel (1% Cr – 2.25% Cr) | E9018-B3, ER90S-B3 (Cr-Mo steel filler metals) |

| 4 | Chromium-molybdenum steel (5% Cr – 9% Cr) | E502, E505 (high Cr-Mo electrodes) |

| 5 | Chromium steel (12% Cr) | E410, ER410 (martensitic stainless steel filler metals) |

| 6 | Chromium-nickel steel (austenitic) | E308, ER308 (austenitic stainless steel filler metals) |

| 7 | Chromium-nickel steel (duplex) | ER2209, E2209 (duplex stainless steel filler metals) |

| 8 | Nickel steel | ENiCrFe-3, ERNiCr-3 (nickel alloy filler metals) |

| 9 | Nickel-molybdenum steel | ENiMo-1, ERNiMo-1 (nickel-molybdenum filler metals) |

| 10 | Manganese-molybdenum steel | E10018-M, ER100S-1 (high-strength low-alloy electrodes) |

| 11 | Other low-alloy steels | E11018-M, ER110S-1 (high-strength electrodes) |

| 12 | High-strength carbon steel | E12018-M, ER120S-1 (ultra-high-strength electrodes) |

| 13 | High-carbon steel | E9018-M, ER90S-1 (high-carbon steel electrodes) |

| 14 | High-alloy steel | E310, ER310 (fully austenitic stainless steel) |

| 15 | Other ferrous weld metals | Specialty alloys not covered by other A-Numbers |

How A-Numbers Are Assigned

A-Numbers are determined by the chemical analysis of the weld deposit, focusing on elements like carbon, manganese, silicon, and alloying elements. For example:

- A-Number 1: Carbon steel weld deposits.

- A-Number 8: Stainless steel weld deposits with chromium and nickel.

The complete list is available in ASME BPVC Section IX, Table QW-442.

Importance in Welding

- Weld Metal Properties: Ensures the weld metal has the necessary strength, toughness, and corrosion resistance.

- Procedure Qualification: Like P-Numbers, A-Numbers reduce the need for multiple qualifications by grouping similar weld metals.

References in Other Standards

- AWS Standards: AWS filler metal specifications (e.g., AWS A5.1 for carbon steel electrodes) often align with A-Numbers.

- ISO Standards: ISO 14343 classifies welding consumables based on chemical composition, similar to A-Numbers.

What is an F-Number in Welding?

Definition and Purpose

An F-Number (short for “Filler Metal Number”) is a classification system for welding filler metals based on their usability characteristics, such as the welding process they are used with and their operability.

- Primary Standard: ASME BPVC Section IX.

- Purpose: To group filler metals with similar welding characteristics, simplifying welder qualification and procedure development.

How F-Numbers Are Assigned

F-Numbers are assigned based on the type of filler metal and the welding process. For example:

- F-Number 1: Covered electrodes for shielded metal arc welding (SMAW) with high deposition rates.

- F-Number 6: Tubular cored electrodes for flux-cored arc welding (FCAW).

- F-Number 43: Aluminum and aluminum alloy electrodes.

The full list is in ASME BPVC Section IX, Table QW-432.

F-Numbers categorize welding filler metals based on usability characteristics and the welding process they are suited for.

| F-Number | Description | Examples of Filler Metals |

|---|---|---|

| 1 | High-deposition SMAW electrodes | E7024, E6027 (iron powder electrodes) |

| 2 | Rutile SMAW electrodes | E6012, E6013 (rutile-coated electrodes) |

| 3 | Cellulosic SMAW electrodes | E6010, E6011 (cellulose-coated electrodes) |

| 4 | Low-hydrogen SMAW electrodes | E7018, E7016 (basic-coated electrodes) |

| 5 | Stainless steel SMAW electrodes | E308-16, E316-15 (stainless steel electrodes) |

| 6 | Gas-shielded flux-cored wires (FCAW) | E71T-1, E81T1-Ni1 (flux-cored wires) |

| 21 | Aluminum solid wires (GMAW) | ER4043, ER5356 (aluminum MIG wires) |

| 22 | Aluminum flux-cored wires | Not commonly used |

| 23 | Aluminum SMAW electrodes | E4043 (aluminum electrodes) |

| 31 | Copper and copper alloy wires | ERCu, ERCuSi-A (copper MIG/TIG wires) |

| 41 | Nickel and nickel alloy wires | ERNiCr-3, ERNiCu-7 (nickel alloy wires) |

| 43 | Nickel-chromium-iron wires | ERNiCrFe-5, ERNiCrMo-3 (Inconel wires) |

| 51 | Titanium wires | ERTi-2, ERTi-5 (titanium TIG wires) |

| 61 | Zirconium wires | ERZr2 (zirconium TIG wires) |

Notes

- A-Numbers: Focus on the weld metal’s chemical makeup, ensuring compatibility with base metals.

- P-Numbers: Simplify base metal grouping for welding procedure qualifications.

- F-Numbers: Standardize filler metal selection based on welding technique and skill requirements.

For the most current and exhaustive lists, refer to ASME BPVC Section IX, Tables QW-442 (A-Numbers), QW-422 (P-Numbers), and QW-432 (F-Numbers).

Importance in Welding

- Welder Qualification: A welder qualified with one filler metal in an F-Number group can weld with other filler metals in the same group without requalification.

- Process Compatibility: Ensures the filler metal is suitable for the chosen welding process and position.

References in Other Standards

- AWS Standards: AWS filler metal classifications (e.g., AWS A5.18 for carbon steel filler metals) are often cross-referenced with F-Numbers.

- ISO Standards: ISO 9606 for welder qualification references similar groupings for filler metals.

Interrelation Between P-Numbers, A-Numbers, and F-Numbers

While P-Numbers, A-Numbers, and F-Numbers serve distinct purposes, they are interconnected in the welding procedure specification (WPS) process:

- P-Number determines the base metal to be welded.

- F-Number specifies the filler metal to be used.

- A-Number ensures the weld metal deposit has the required chemical composition.

Together, these classifications streamline the development and qualification of welding procedures, ensuring that the right materials and processes are used for each job.

Practical Applications and Examples

Example 1: Welding Carbon Steel Pipes

- Base Metal: ASTM A106 Grade B (P-Number 1).

- Filler Metal: E7018 electrode (F-Number 4).

- Weld Metal: Carbon steel deposit (A-Number 1).

Since both the base metal and weld metal fall under P-Number 1 and A-Number 1, respectively, a single welding procedure can be used for similar carbon steel pipes.

Example 2: Welding Stainless Steel Tanks

- Base Metal: 304L stainless steel (P-Number 8).

- Filler Metal: ER308L (F-Number 6).

- Weld Metal: Austenitic stainless steel deposit (A-Number 8).

Here, the P-Number and A-Number ensure compatibility between the base and weld metals, while the F-Number confirms the filler metal’s suitability for the welding process.

Global Standards and Cross-References

While ASME is the primary source for P-Numbers, A-Numbers, and F-Numbers, other international standards provide similar classifications:

- ISO 15608: Material grouping for welding, akin to P-Numbers.

- ISO 14343: Classification of welding consumables by chemical composition, similar to A-Numbers.

- ISO 9606: Welder qualification based on filler metal groups, comparable to F-Numbers.

- AS Standards: Australian standards often reference ASME classifications for welding procedures and qualifications.

Understanding these cross-references is crucial for welding professionals working on international projects or with materials certified under different standards.

Conclusion

P-Numbers, A-Numbers, and F-Numbers are indispensable tools in the welding industry, providing a systematic way to classify base metals, weld metals, and filler metals. By simplifying procedure and welder qualifications, these numbering systems enhance efficiency, safety, and quality in welding operations.

For welding engineers, inspectors, and technicians, a thorough understanding of these classifications is essential. Whether you’re working on a pressure vessel, pipeline, or structural steel project, knowing how to apply P-Numbers, A-Numbers, and F-Numbers will ensure your welding processes meet the highest standards.

References

- ASME Boiler and Pressure Vessel Code, Section IX: Primary source for P-Numbers, A-Numbers, and F-Numbers.

- AWS A5.1/A5.1M: Specification for carbon steel electrodes, referenced in F-Number classifications.

- ISO 15608: Welding – Guidelines for a metallic materials grouping system.

- ISO 14343: Welding consumables – Wire electrodes, strip electrodes, wires, and rods for arc welding of stainless and heat-resisting steels – Classification.

- ISO 9606: Qualification testing of welders – Fusion welding.